However, since the actual interval is for 4 hours, the line that states 10000 milliseconds has to be changed to 14400000 milliseconds.

Sunday, May 31, 2015

Week 8: Changing intervals

The Arduino is very beneficial for the pet feeder. The pet feeder is going to be presented in front of a panel of people. The pet feeder is meant to rotate 45 degrees every 4 hours, however, the time interval has to be accelerated in order for the judges to observe how the machine works. The fact that an Arduino is being used allows the group to simply change one line of code to change the time interval at which the top of the pet feeder rotates. The rotation will now occur every ten seconds to quickly display the use of the feeder.

However, since the actual interval is for 4 hours, the line that states 10000 milliseconds has to be changed to 14400000 milliseconds.

However, since the actual interval is for 4 hours, the line that states 10000 milliseconds has to be changed to 14400000 milliseconds.

Week 7: Inner Compartments

This is the general shape of the compartments:

[PIC]

The servo's axis of rotation is not exactly at the center:

C=1.352"

L=0.174"

So the maximum distance from the centerpiece to the edge is 1.526 inches. This means that the centerpiece's interior needs to be larger than 3.052 inches

[PIC]

[PIC]

Limitations

There are a few limiting factors to keep in mind when designing the inner compartments:- The center needs to be large enough to house the mechanical/electrical workings

- There needs to be 8 compartments for 4-days worth of food

- The compartments need to have a minimal number of nooks for easy cleaning

- The design must keep in mind the limitations of the printer

- The printer prefers small pieces to larger ones

- The printer prefers a minimal amount of material used

- The printer cannot print dimensions larger than 12 inches

- The pieces must completely separate the food compartments from the electrical components

- The compartments housing the food must be adequately separated from its neighboring compartments.

Combating these limitations:

1 The Center

The servos is the only piece of hardware that will be in the space of the of the centerpiece.The servo's axis of rotation is not exactly at the center:

|

| From servocity.com |

C=1.352"

L=0.174"

So the maximum distance from the centerpiece to the edge is 1.526 inches. This means that the centerpiece's interior needs to be larger than 3.052 inches

2 Eight Compartments

The compartments must allow for multiple days of convenience and care. The entirety of the container can be swept radially from the center by 360 degrees, so the mid-line of each eighth needs to be 45 degrees from the previous.3 Easy Cleaning

A way to avoid corners made by the meeting of the floor of the container and a vertical ____ is to camber the corners. The assembled piece(s) will slope downward to achieve this effect.[PIC]

4 Printing limitations

The lab is equipped with a few printers, each with ____ of function. The largest prints a maximum of ______ and it is preferred that the pieces being printed take under __ hours to print and that they don't use under 1 cartridge of material.5 Separating electrical components

Thursday, May 28, 2015

Week 7: Elevating the Servomotor

Now that the central piece and dividers have been made and set up within the Feeder, we need to look at positioning the servomotor so that the aluminium Hub Horn [1] of the servo aligns perfectly at the centre of the Feeder cover.

Measurements (Feeder Cover):

Diameter of plexiglass Feeder cover - 13in

Central point of Feeder cover - 6.5in

Diameter of Aluminium servomotor Hub horn - __in

The Servomotor will be located within the closed-off central piece and will need to be elevated in order for the hub horn of the servomotor to be able to attach to the Feeder cover. The basic structure requires the Servo be fastened to a flat surface (circular plexiglass sheet) that will fit exactly into the central piece. This surface will need to have an opening/hole that allows the servo's control wire to lead to a separate electrical compartment (located below Feeder container). Because the hub horn is offset from the central point of the servomotor, the servomotor's position on the plexiglass surface will need to be relative to the alignment of the hub horn and the central point of the Feeder cover.

[INSERT PIC__drawn out image]

Measurements (Circular Plexiglass Sheet):

Diameter of plexiglass servomotor support surface -

Diameter of supporting plexiglass ring -

Height of Servomotor -

Height of elevated surface relative to base o the Central Piece -

Measurements (Feeder Cover):

Diameter of plexiglass Feeder cover - 13in

Central point of Feeder cover - 6.5in

Diameter of Aluminium servomotor Hub horn - __in

|

| Fig 1. Aluminium Servo Hub Horn |

The Servomotor will be located within the closed-off central piece and will need to be elevated in order for the hub horn of the servomotor to be able to attach to the Feeder cover. The basic structure requires the Servo be fastened to a flat surface (circular plexiglass sheet) that will fit exactly into the central piece. This surface will need to have an opening/hole that allows the servo's control wire to lead to a separate electrical compartment (located below Feeder container). Because the hub horn is offset from the central point of the servomotor, the servomotor's position on the plexiglass surface will need to be relative to the alignment of the hub horn and the central point of the Feeder cover.

[INSERT PIC__drawn out image]

Measurements (Circular Plexiglass Sheet):

Diameter of plexiglass servomotor support surface -

Diameter of supporting plexiglass ring -

Height of Servomotor -

Height of elevated surface relative to base o the Central Piece -

Week 7: Inner Compartment Dividers

As mentioned previously, 8 food compartments will divvy up the available space to carry up up to 4 days worth of food. These compartments will be separated into equal volumes by means of 8 compartment dividers.

Based off of internal measurements, the dividers were cut to fit into the remainder of space after factoring in the central piece.

Internal measurements:

Inner diameter of Feeder container (Cake Tin) - 12in

Outer diameter of central piece (PVC pipe) - 4in

Height of Feeder container and central piece - 3in

Divider Measurements:

Length - 4 & 1/16in

Height - 3in

Thickness - 1/16in

Chamfer -

Based off of internal measurements, the dividers were cut to fit into the remainder of space after factoring in the central piece.

Internal measurements:

Inner diameter of Feeder container (Cake Tin) - 12in

Outer diameter of central piece (PVC pipe) - 4in

Height of Feeder container and central piece - 3in

Divider Measurements:

Length - 4 & 1/16in

Height - 3in

Thickness - 1/16in

Chamfer -

|

| Figure 1. Plexiglass Compartment Dividers |

Tuesday, May 26, 2015

Week 6: Drawbacks & Solutions

This week, the group was met with its first set of drawbacks. We have now reached the stage of project where the Feeder design is concrete and prototyping has officially gone underway.

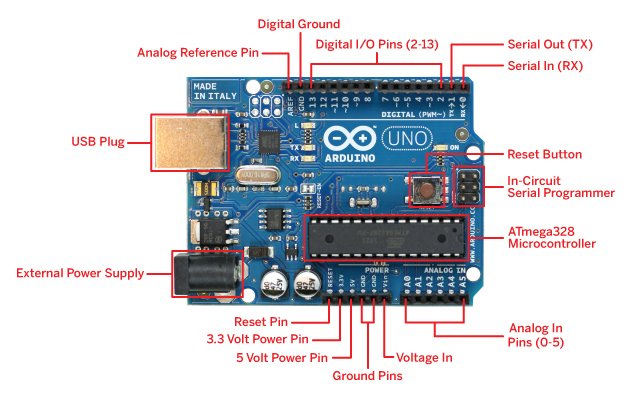

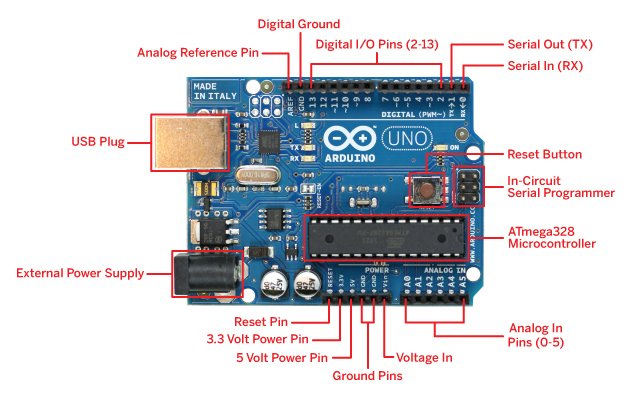

Having received the Servo Motor necessary to revolve the plexiglass feeder cover, alongside the Arduino Uno, batteries and the minor parts that complete the electronic section of the feeder, the team has begun working on the programming necessary to run the servo motor. During the first round of testing; using a Servomotor, the Arduino Uno, and a 9V battery power source to test the rotation of the servomotor, our initial servomotor was burned out. Due to the high voltage of the 9V battery compared to the 4.8 - 6V range of the Servomotor the Servo overheated and was fried. On purchasing a new servomotor, an alternative power source was used. Instead of the 9V battery, a battery pack that consists of four AA batteries was used. This successfully ran the servomotor. In further posts, another reason for the use of the battery pack is highlighted.

The second drawback concerned the circular plexiglass Feeder cover. Due to the brittle nature of the plexiglass; on attempting to sand down the rough edges of the cover, the feeder snapped in half. A new cover was cut, adding one inch to the diameter so as to increase the coverage of the feeder.

The second drawback concerned the circular plexiglass Feeder cover. Due to the brittle nature of the plexiglass; on attempting to sand down the rough edges of the cover, the feeder snapped in half. A new cover was cut, adding one inch to the diameter so as to increase the coverage of the feeder.

Week 6: Soldering

An issue arose recently with the entry points of the servo motor. There was a lead of a wire that broke off inside the entry point of the servo wiring. The lead was incredibly difficult to remove, the wires were separated from the piece that kept them attached.

The separated wires were later soldered using a soldering iron. The wires were soldered to the wires that would be connected to the Arduino. There were issues with the soldering iron because it was relatively old and could not properly connect the wires together at first. Now, the issue has been adverted and the circuit works properly.

|

| The lead was stuck in the black piece connecting the wires, which was later removed |

Monday, May 11, 2015

Week 6: Portability

The selling point of this pet feeder is that it is portable. Because it has to be portable, the power source of the Arduino cannot be 5 volts of power the computer is delivering to the Arduino. Therefore, the best method to make the pet feeder portable is by attaching a five volt battery pack to Arduino in its external power source pin.

The initial issue that the motor could not handle a nine volt battery because it was a 4.8 volt to 6 volt motor. Therefore, an ideal voltage for the motor is 5 volts. However, a battery pack wired in series would be perfect as a external power source. Most likely, there will be four 1.5 volt AA batteries supplying a total of 6 volts of power. In addition, the battery pack is fairly small so it will properly fit in the section underneath the tin pan.

The initial issue that the motor could not handle a nine volt battery because it was a 4.8 volt to 6 volt motor. Therefore, an ideal voltage for the motor is 5 volts. However, a battery pack wired in series would be perfect as a external power source. Most likely, there will be four 1.5 volt AA batteries supplying a total of 6 volts of power. In addition, the battery pack is fairly small so it will properly fit in the section underneath the tin pan.

Monday, May 4, 2015

Week 5: Pet Feeder Cover (Plexiglass Sheet)

|

| Fig 1. Plexiglass Sheets |

- Glass-like qualities - clarity, transparency, translucence - but at HALF the weight

- Stronger impact resistance (10 times greater than glass) and more durable

- Ability to be coated, tinted, coloured, mirrored or made opaque to enhance features such as: scratch-resistance, anti-fogging, solar-reductive

- Smooth surface that would provides little to no resistance when in motion

Due to the easy accessibility and low cost Plexiglass is the most cost efficient material whose physical properties meet the needs of the feeder cover. We were able to mould the sheet to the exact shape necessary to cover the Feeder, as seen below:

|

| Fig 2. Pet Feeder - Plexiglass Acrylic Sheet Cover |

Basic Dimensions of Feeder Cover:

Outer Radius (In contact with cake tin) - 6 inches

Inner Radius (Length of compartment opening) - 4.5 inches

Thickness (Of Plexiglass sheet) - 3/32 inches

Angle (Of Compartment opening) - 45˚

Week 5: Back to the Arduino (Official Switch to Digital Approach)

After considering realizing the difficulty and the danger that would come with working with high the high voltage that would be sent to the timer switch from the outlet, we decided against using the timer switch. The main problem was as I said, the issue with the danger associated with the high voltage and high amperes, therefore, we went back to using the Arduino. The Arduino will be connected to a motor, which will rotate according to the certain degree angles that we input into the Arduino program.

The initial issue with using the Arduino was that we were unsure on how to place it in the system, but now that we have created a hole in the bottom of the cake pan, we will simply lift the pan and place the Arduino underneath the system. We now realize that the Arduino language is a very learn-able language with a section where the user has to input the variables and another section where the user has to insert a prompt that will continue to loop. The Arduino is perfect for our pet feeder system. However, we will need a servo motor for this situation because with that, the Arduino will send pulses to the motor, which will rotate at preset angles. Making a simple DC motor rotate at certain angles and time intervals, would be quite difficult. Therefore, we will use a servo, which we will speak about later.

|

| Format of a sample Arduino code |

Subscribe to:

Posts (Atom)